Machine builders used to have to compromise when it came to modularisation: they either adapted the control system to suit the required complexity, opting for central or decentralised concepts and risking a break in extensibility, or they selected a central control even though it was hardly necessary for more straightforward applications. Lenze has now resolved the conflict by extending the automation system. Seamlessly scalable solutions are now available for the smallest machine module with only one axis of movement through to complex multi-axis systems. This lets OEMs respond flexibly to every application case without a break in system – and without having to adapt a single line in the software code.

For decades machine builders have focused on three things: performance, availability and quality. However, time-to-market has now become a crucial challenge: how fast can a machine go online at the user’s site? The answer lies in the deployment of modular concepts. Valuable time can be saved on engineering, programming and structuring when most of the solution can be devised using a modular principle. On the other hand, flexibility must not be allowed to suffer. Initially this relates to customisation but later on in the plant life cycle it is also a matter of extensibility, such as adding movement axes or whether innovative technologies can be retrofitted without an excessive amount of time and money being spent on the process. Ultimately, modularisation can only succeed if everything is cast in the same mould: mechanics, electronics and software.

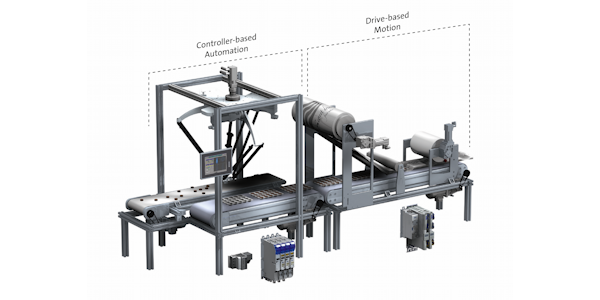

Consistent automation

With its addition of a new servo drive system with integrated control, Lenze offers all the necessary modules for machine and plant builders to attain open seamless modularisation without having to tolerate compromises. The question of central or decentralised control becomes redundant as they can draw on a coherent product portfolio of hardware and software that provides access to both topologies. The basis is formed by module programming via the FAST application software toolbox. If necessary, cross-modular synchronisation can also be achieved for a more complex machine. No reprogramming is necessary – the application software runs on decentralised and central controllers alike. FAST also simplifies engineering as many control and motion functions come as ready-to-use software modules. Machine builders are no longer required for programming, rather they are merely configured with application-specific parameters.

Conclusion

Lenze’s enhanced portfolio offers a consistent automation system for finely scaled combinations. Solutions cast in a single mould are available for machines with one movement axis through to multi-axis systems with a high-performance central control for more complex machines. This lets machine builders pursue a modular approach to machine development and brings highly flexible smart and, more importantly, customised machines to the market as quickly as possible.

Picture: Lenze automation platform supported by modular concepts, © Lenze SE 2017